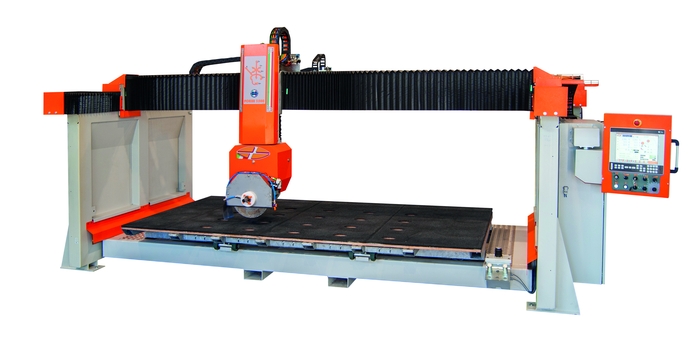

Squaring dimensions 3500 x 2100 mm.

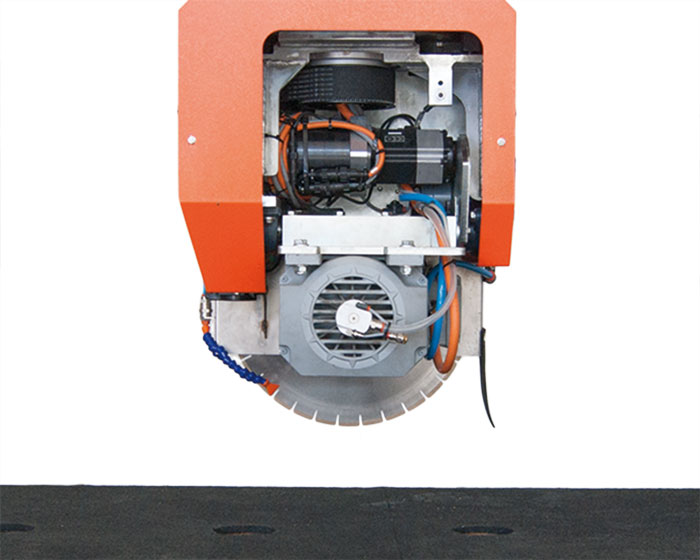

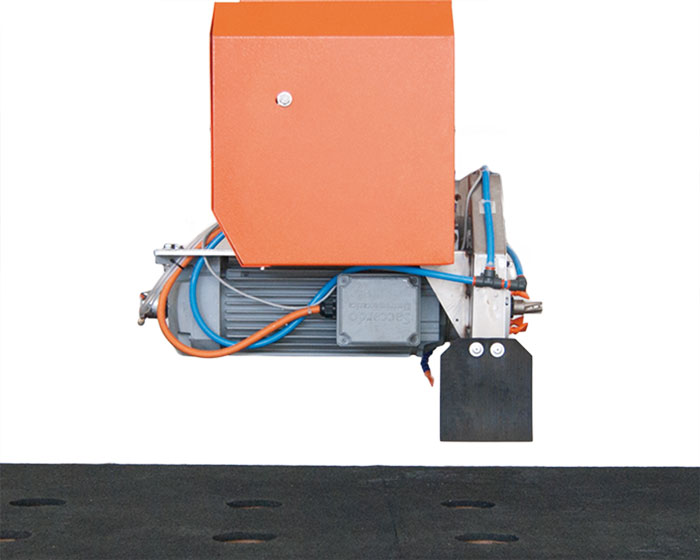

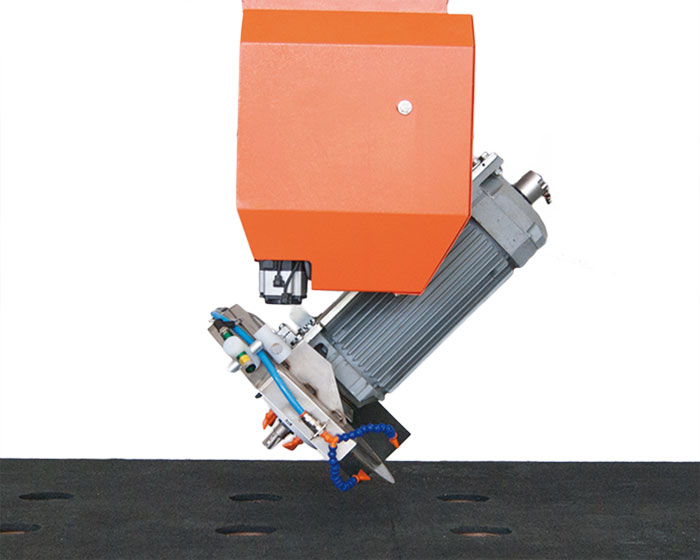

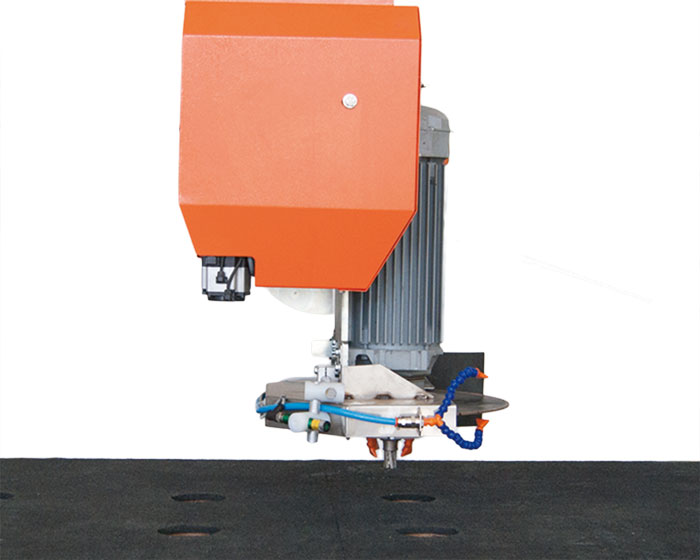

Hot-dip galvanized tilting bench with 5 motorized and interpolating axes, suitable for processing natural stone, synthetics and porcelain stoneware.

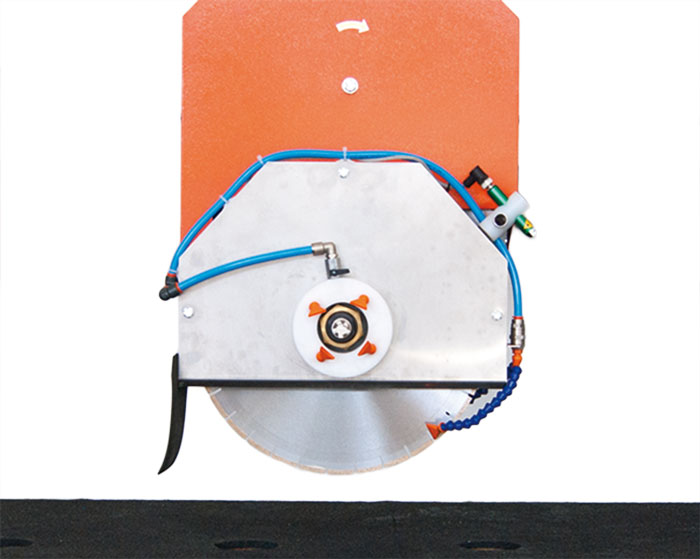

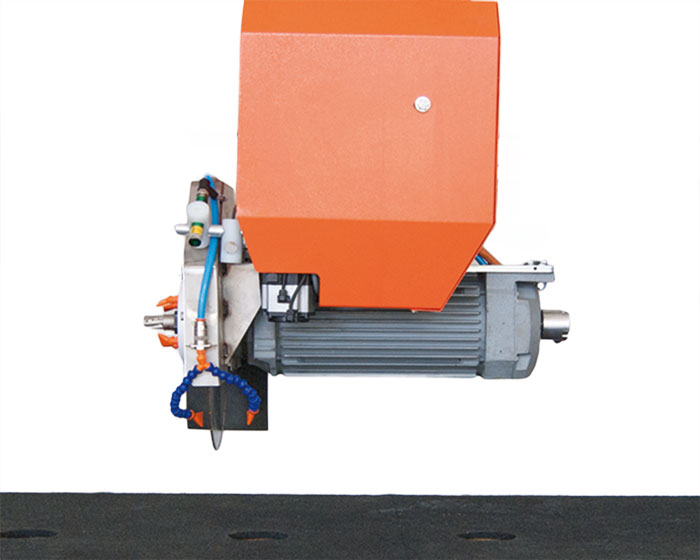

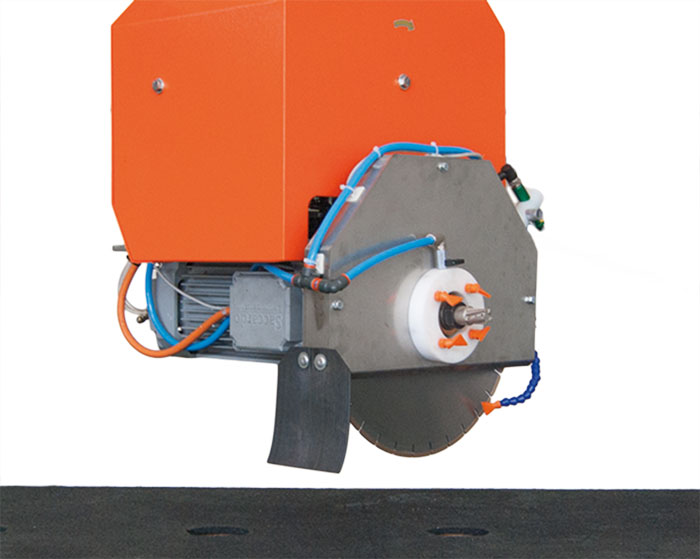

Inverter for adjusting the rotation speed of the disc (from 600 to 6000 rpm) as standard.

20 automatic functions.

CNC con display 15 " touchscreen.

Simple and intuitive "Touch and Go" interface.

Structure and track with ceramic-based paint resistant to corrosion over time.

Spindle equipped with 1/2 gas connection for core bits and cutters.

STANDARD EQUIPMENT:

Laser marks green cut, plate support stops, disc diameter measuring device.

OPTIONAL:

Side stops, LED light for lighting the work area, PVC tank for collecting water equipped with pump, slab thickness detection device, remote control, CAM software, CAD- CAM software, PC with dedicated support, installation positioning and operator training.